-40%

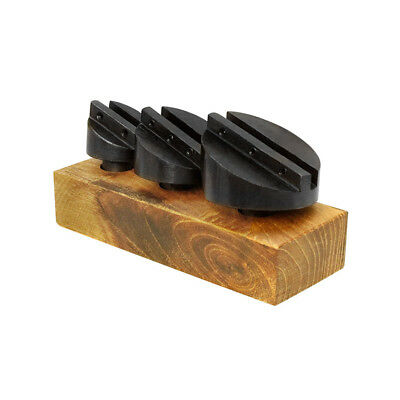

small/medium balanced fly cutter, fly cutter,face mill, surface flycutter,shell

$ 152.59

- Description

- Size Guide

Description

Please take the time to read this very carefully you need to mentionSMALL or MEDIUM

PLEASE when ordering the tool MENTION WHICH ONE YOU NEED FOR YOUR APPLICATION BETWEEN THE «SMALL» AND THE «MEDIUM» TOOLS

Auction is for the Fly Cut Thor  only.....

without any arbor

, the arbor you see in the auction is only to show how it is mount on the tool

This auction is for «ONE» fly Cut Thor,just let me know which one you want ,

small or medium size,

The small Fly cut thor is set to machine 4.200 inch without counterweight or 7.800 inch diameter with counterweight install or the «Medium» machine diameter is set to machine 6.200 inch without the counterweight and 11.300 inch in diameter with the counterweight install

both the small and the medium size Fly Cut Thor use a pilot of 1.250(1 1/4 inch ) x .500 keyway(1/2 inch)

The

«Fly Cut-Thor»

is

the new type of fly cutter, which is going to set new standard in today’s machining world, metal surface removal at its best.

I simply call this new tool the «

Fly Cut-Thor

»,

for many reasons and you will soon really discover that reason when you first use it.

With this new tool design, rotational speed will not be an object anymore, the design of this tool can accommodate any given speed you couldn’t usually achieve with any other type of small to larger surfacing tool with one insert, it is simply

«balance»

by the design of it, it could be run at any given speed on any type of material ,with the use of PCD/CBN inserts high speed machining could be obtain with the tool either set at its minimal size or set at its maximal size when using  the counterweight , this very rigid new tool design can produce fast cutting action with a higher speed and  feed rate than any other large fly cutters.

You own a small or even a big machine shop, you’re working as a machinist/toolmaker in a shop or even working in your basement as a hobbyist machinist, you’ve deal with metal removal in different ways, you sure know by now that the faster and cheaper it cost,…is the better for you, you’ve probably been thinking what you should need to combine real efficiency, like operate the machine faster and that would cost really cheap to run, well this tool can do all that and more.

Been dealing myself with this for years, with large multiple inserts cutters, that cost high dollars to operate, leaving poor swirl finish and really not giving me what I paid for at first, not to count that every time one insert was chipped all the others need to be change, got really tired of all this, so I was looking for a way to improve my machining time and most of all cost lot less to operate, so I come up with this design, giving you the option to have 2 different size of cutters with the same tool, smaller to larger machining surface with the same tool, is like having 2 surfacing tools in one.

Believe me, this new tool will save you time, will cost cheaper to run and can turn at any given speed than any other large tools of the same size on the market.

It is made to set new standard in metal removal on any surface.

It is a completely new design, this tool was created by me years ago with one thing in mind, to save time and cost less to operate, now it’s time for others to benefit from this amazing tool ….Time is money, the more you save the better it is.

Always looking to lower your tooling’s cost , this is really a great solution, this tool can easily replace many others at a much lower cost per use than any others, this new tool design use a very solid and common «Trigon» negative insert, that is virtually used in all machine shop around the world, combine to a high quality made and very rugged American made «Trigon» insert holder, ,this is mount on a new design fly cutter, that are capable of reaching quite high RPM without being affected by vibrations, which is often a problem with large fly cutters.

This new amazing tool design will simply pay for itself in a very short period.

I’m telling you, stop your search, you just found it; it is a new tool design that is calls the

«

Fly Cut-Thor

».

Everyone would want to have one.

Most large fly cutters on the market all use similar designs, with either one or multiple hss or carbide tools bits, usually lots of overhang from the tool itself to cover a large machining surface, make the tool unbalance all the time so you need to slow your speed to compensate for that lack of balance, also the lack of rigidity from the tool and the machine come in the equation, meaning less depth of cut, just to name a few, those problems will leave out with poor surface finish and lots of chatters/vibrations, not to count the lost of machining time.

Most of the times, you are restrain by the surface area you can machine down at any given times, or even at the speed you should set your machine without being bothering by vibration, the surface finish the tool will leave, even the tool broke up or simply wear out, with this new tool design, one cut can take care of a whole surface area in one and only pass, and the insert will still be fine.

Vibration due to cutter speed and lack of rigidity of the tool will be things of the past, after only a little use of this tool you will find the perfect RPM and feed for your machining need, you will probably use it in many more application than you were ever thinking, fast material removal with very minimal cost at the end.

This tool was first design to remove material faster and cheaper than any others on the market, but remember that it was not made at first to replace very large face mill using multiple inserts, but will certainly keep up with many of those, Â for a lot cheaper, plus an extra, it will leave excellent surface finish compare to any of them.

Feed per minutes is usually less with a one insert tool design, but you all know that surface finish is always the best when using only one insert, one insert will not interfere with any others; it will leave you a perfect surface finish at the end.

This tool is the best compromise you can find for speed and feed and depth of cut compare to others. You will be amaze by the speed, the feed and also the depth of cut this tool can reach.

Any machine shop should use this special tool; it is capable of machining either small to quite large surface with a larger depth of cut than many others, all that at an extremely low cost per use.

This FC6-11 Fly Cut-Thor(this is the

Largest

size in the series of 2 tools) comes with one American quality made tool insert holder, with 2 excellent quality grade inserts(one ISCAR brand insert WNMG 432 for steel and tool steel and one INGERSOLL brand insert WNMG 432 for non ferrous metal) that are capable of running in interrupted cut.

Note

:

and not included in the auction, the «arbor/ holder», you will need is to buy a shell/face mill holder of 1 ¼ inch with ½ inch key drive ,you probably already own one in your shop.

Here is testimony from customers

Hi, I have tried it now and am quite happy with it. At first, I had trouble attaching inserts, and later attaching my arbor, but I worked through both issues and have done some experimental cuts on some scraps with the short setting of the cutter with good success.

The arbor issue was that I couldn't insert my arbor more than about 1/10" or so without it binding up badly. After researching discussions on the web, the likely culprit seemed to be that my inexpensive Grizzly arbor was probably slightly out of tolerance, so I shaved its diameter until I was able to get it to fit without requiring excessive force or binding badly.

So far, I have done experimental spins with the the short cutter (without the counterweight) up to about 1200 rpm on my mill without any worrisome vibration. I didn't try going any higher, as I hadn't yet locked down the screws with Loctite as recommended, and that was approaching the recommended cutting speed for aluminum anyway. I have done a couple trial finishing-style facings on some scrap aluminum blocks that I am happy with, so I think I will be quite satisfied with it.

What really attracted me to this cutter was that it both used inserts and was balanced. I had almost got another indexable cutter that wasn't balanced, and was quite relieved to find a balanced fly cutter.

thanks,

--Tim

Hi Ray,

I got the cutter on Monday but just had a moment to put it together and give it a spin.

I could tell right away this piece was way more like you had described. All of it fits together perfectly, even the counterweight looks better when it’s bolted up . I just put it in my mill and turned it on and spun it at 650...smooth as silk. Started turning the dial up and got just up over 1000 and decided that was plenty fast. Not even a hint of vibration!

Thank you !! Nice to deal with someone that cares about their product for a change!

littlee39

This is the best flycuter i have ever used in my 35 years of machining.....

shannamc1982

This tool range is f

rom 6 ÂĽ without the counterweight to 11 ÂĽ inch with the counterweight installed ,(6Â 1/4 inch diameter surface machining without the counterweight installed and 11 ÂĽ inch surface machining with the counter weight installed)

I have one other size available, that varies from either, 3 Âľ inch (without counterweight installed) to 7 inch (with counterweight installed) for the smallest ones.

With the two

«

Fly-Cut Thor

»

you should be able to machine surface from 3 3/4 inch to well over 11 inch.

This new tool design can be used on basically on all type of machine usually use in modern industries, but can also be use on small vertical mill at home as well.

Uses a WNMG 432 «Trigon» series un-coated inserts for milling, aluminum and plastic or even cast iron (special insert uncoated, see below) and a WNMG 432 «Trigon» tin coated inserts for steel and tool steels and other ferrous metal.

Cast iron

:also use a uncoated insert, but differs in grade from the one supplied for non ferrous metal, I also have the cast iron insert on hands if you need them, at a slight extra cost, all my inserts are excellent quality brand, like I mentioned before ,and the grade I supply are made to withstand interrupted cut and tool wear, which is often the case on many large surface machining.

Other inserts can also be use with these Fly Cut Thor giving you more effective and lasting results

(BUT NOT SUPPLIED)

like

Polycrystalline Diamond

and

Cubic Boron Nitride

, commonly referred to as PCD and CBN respectively.

Each with their own characteristics, when used in tool making, these materials will provide very long lasting, rugged tooling for arduous applications used in making parts for the automotive, aerospace and mining industries and more.

Perhaps the most distinct difference is in their thermal stability. Unlike

PCD tools

used mostly on nonferrous materials,

CBN tools

maintain thermal stability and hardness levels in higher temperature applications. CBN characteristics include its abrasion resistance, thermal and chemical resistance and maintaining sharp edges when cutting – which are most effective when machining ferrous materials.

The speed and the depth of cut are mostly determined by the machine capacity.

Note:

It is always recommended to set the machine at the recommended RPM and feed for the material to be use to avoid ruining the insert, even if rpm in this case could be set at an higher speed than necessary, but once you did use this tool on several surfaces and determine which works better for you, you will simply love the way it works, and the money you already save from using it, will serve you elsewhere.

«I did several tests over times ,one of them I captured on video many years ago as a prototype model,I was using the 11 inch «Fly-Cut-Thor» with the counterbalance weight installed, with almost a 3/8 inch depth of cut in aluminum, tool was turning at 1500 rpm(I did try 3000 rpm and up on initial start up, with a feed rate of 15 inch minutes, really smooth machine operation, but only problem was the old Mazak simply stalled at the middle of the cut, with the 7.5 HP electrical motor)

, need to reset the machine, then reduce the speed and feed to 7.5 inch minutes, (not enough power for that depth of cut) to finish the cut, insert was like new at the end, all that without any coolant.»

When doing all kind of machining of surface on any given type of material, like aluminum cylinder heads or decking a cast engine block for example, this tool will give you a superior finish in less time than any others, money wise it will cost you less to operate than any other large fly cutters out there. A single «Trigon» negative insert should last through many projects and no need to use any type of surface grinders, the surface finish leave by the tool is smooth enough to save those costly operations, this tool is also great for one pass squaring of work pieces in any production runs on conventional or CNC machines.

The two

«

F

ly Cut-Thor

»

are both treated with Hot Black Oxyde to give them a nice surface finish and also for corrosion resistance.

This new tool was design and is proudly made right here in Canada, with the use of an American made insert holders and inserts, it is not a cheap far east stuff, but the real deal.

Any parts needed, can be ordered directly from me.

I could also ship anywhere in the world but Canada post air mail outside North America is expensive like 100 dollars to ship

Remember that when you buy a quality tool, it will last you a very long time and pay for itself really fast, thanks for looking. Ray